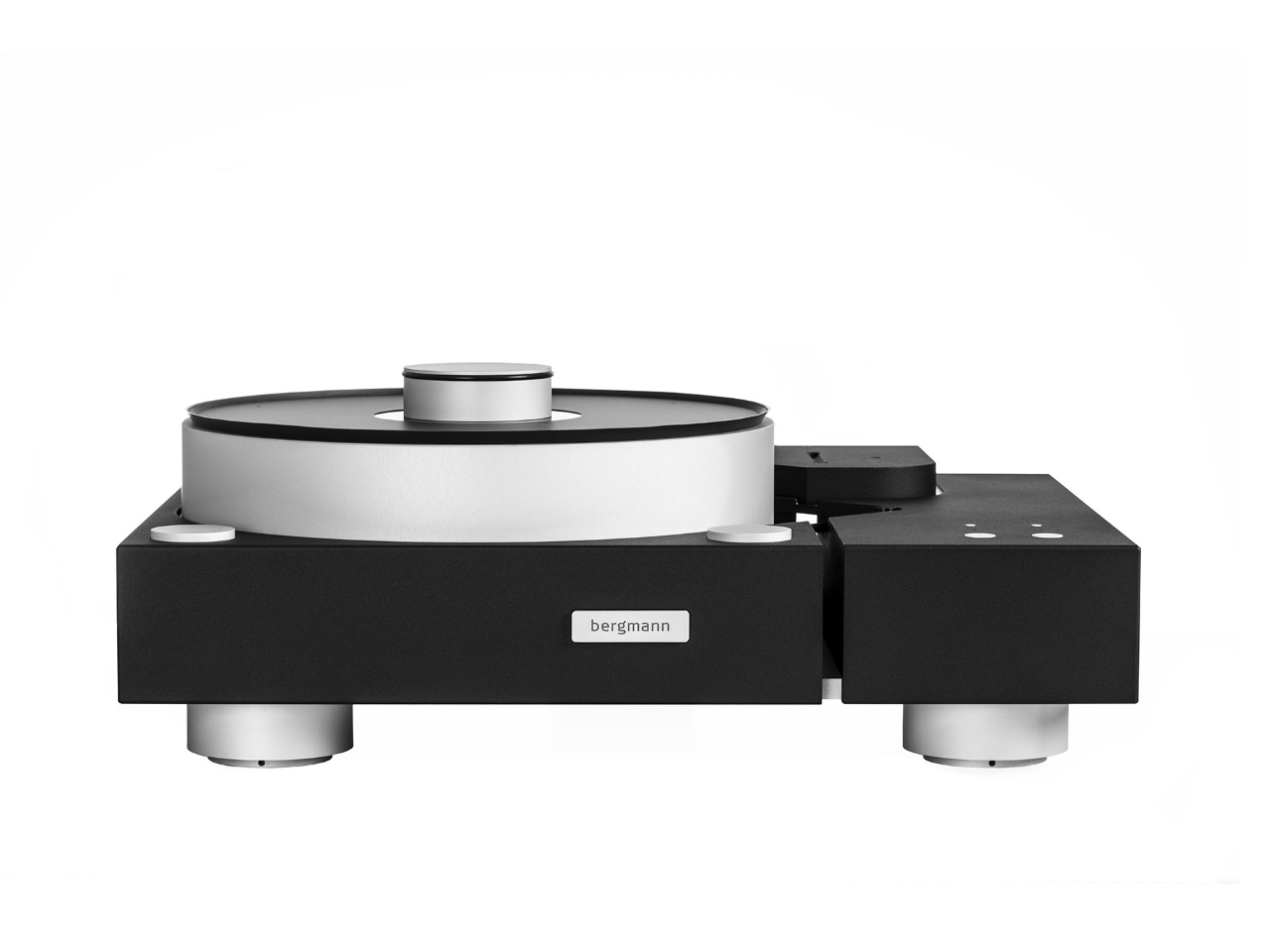

Galder turntable from Bergmann Audio, is Bergmann`s answer to the most universal turntable design.

Galder & Odin

In the Nordic Mythology, Galder means to enchant. A craft consisting of magic songs and spells. A master of practice Galder craft, was said to be able to raise storms, make distant ships sink, make swords blunt, make armour decide victory or defeat in battles. Odin, a master of magic, was a God with great abilities to “Galder”.

Advantage of using air bearings

The platter is centered by a steel spindle, running in a very frictionless, low noise and hard wearing polymeric bearing material, and floats on a thin air cushion, which lower the mechanical bearing noise to an absolute minimum- if any. (A traditional bearing solution, which keep the platter centered AND support the platter weight, makes a higher level of mechanical bearing noise, as the contact point between spindle top and platter, generates a very high pressure – and hereby noise.)

By floating on an air cushion, the platter also gains the advantage of a very good isolation from the surroundings, same way as the known -and very expensive- air supported shelfs, used in many highend audio systems.

Also the speed stability benefit from the air supported platter. The musical flow is really extraordinary – not necessarily measurable but audible.

Plinth

The plinth is made of one solid piece of cnc-machined die cast aluminium, as wel as the motorbase. Both parts with powder coated finish. The plinth is securely tightened to a 10mm aluminium bottom plate, which is standing on 3 adjustable feet. The feet is an aluminium and ceramic ball construction. 3 upper and smaller ceramic balls configured in a triangle, is standing on top of one bigger lower ceramic ball. No matter the feet position, the 3 upper ceramic balls will always have a perfect contact to the lower ceramic ball. The motor base is standing on the aluminium bottom plate –but decoupled – and will always be aligned with the plinth, no matter the feet position. On the back side of the plinth, the back panel is mounted. It consist of: Grounding, Air input, Vacuum input, output for an air bearing tonearm, and air adjustment valves for platter and tonearm.

Motorbase

The motorbase on Galder is equipped with a DC tacho motor. Communication between the tacho and the high precision motor control electronic, will keep the platter in a very accurate speed. We measured 0.0027% speed variation! The power supply for the motor control electronic, is build into in the air supply box, to keep high voltage distant from the inter connects delicate signal transmission. Connection is by a 5 meter shielded cable with LEMO connectors.

The air supply is remote controlled from the motorbase. By pressing ether 33 or 45 rpm, first press the air supply goes “ON”, and second press the platter starts to spin. When turning “OFF” the selected speed, the air supply goes “OFF” automatically after 2 minutes. Very user friendly and convenient.

Air supply

The air supply has been the object of our greatest attention. The goal is to design a silent air supply, which could be placed in the listening room, and deliver an even, clean and dry air flow. The pump is an oil free, long life unit, which do not require much maintenance. The impulses from the pump are absorbed in an encapsulated reservoir. This results in an even airflow to the air bearing. The air supply is mounted with a filter, which prevents dust particles in entering the system. This filter is replaceable when necessary.

Vacuum hold down

There are different way to flatten a record, and secure that the record have a good contact to the record mat/platter. A clamp covering the record label, will only keep the center of the record perfectly flattened. A metal ring, on the outer etch will only keep the outer part of the record flattened. The only way to flatten the record completely, is by obtaining a vacuum between the record and the mat/platter – vacuum hold down.

The vacuum hold down invented by Bergmann Audio, is the most user friendly system. The vacuum pump – which is in the air supply box – doesn’t need to be turned “OFF”, when changing record. The user simply remove the vacuum clamp that is covering the center spindle, and the vacuum is released, and the record can easily be changed while the platter is still spinning.After changing the record, put back the vacuum clamp, and the record is automatically flattened by the vacuum hold down system.

Armboard

Galder accept up to 4 tonearms – radial- and linear tracking tonearms. As standard, Galder comes with a main armboard, to fit almost any tonearm brand on the market – 9”, 10” and 12” tonearms. We customize additional armbords for the tonearm brand you want to mount on the Galder turntable.

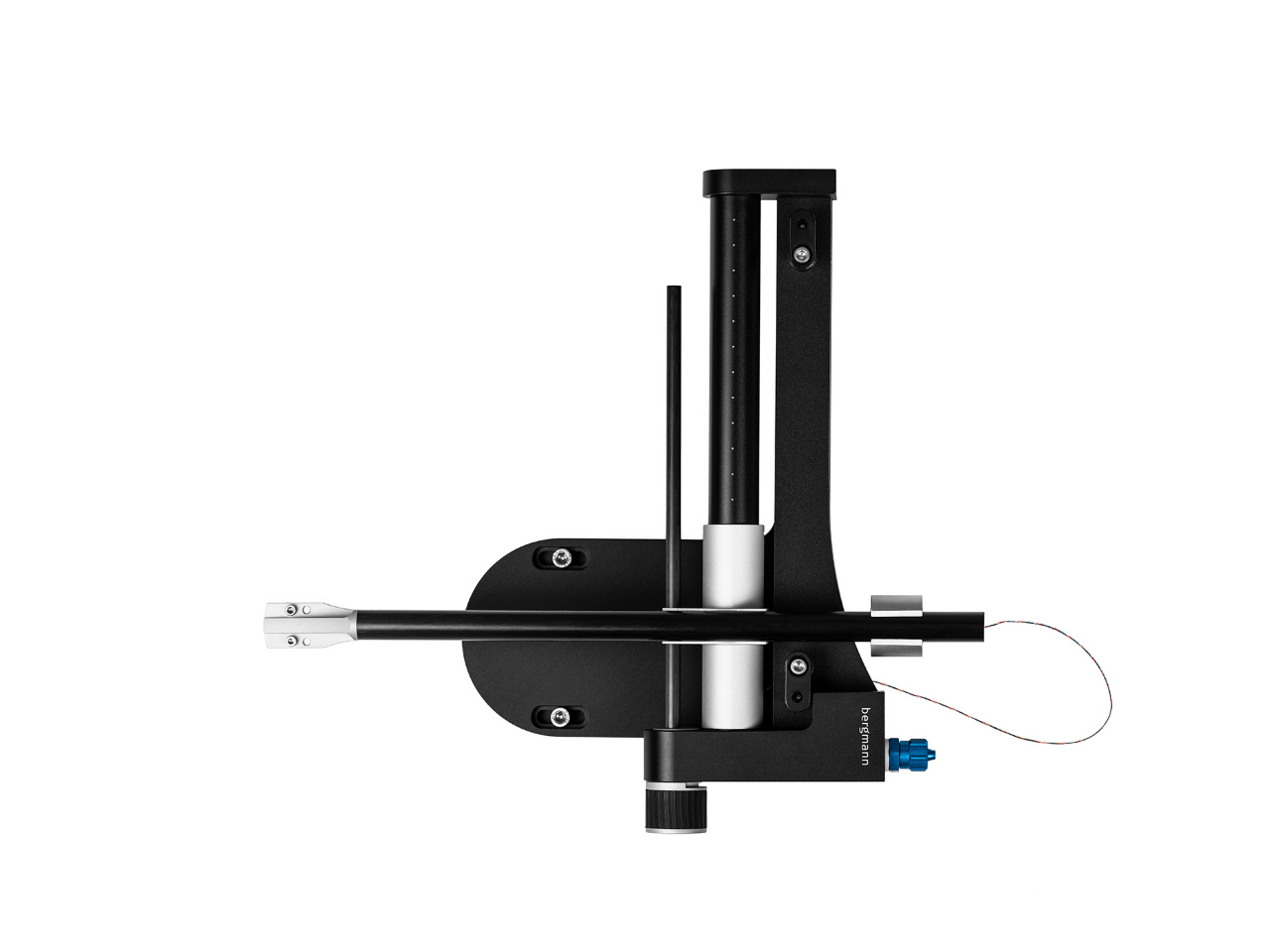

Odin

In the Nordic Mythology, Odin is an extreme central God. Together with his brothers, he is creator of the world and man. Odin is the wise God. He is also the God of poetry, providing the poets with ecstasy and wisdom to express themselves. As a God of war, Odin also plays his role, and acts more like the strategist, who sets up his army, and as the God who ensures victory.

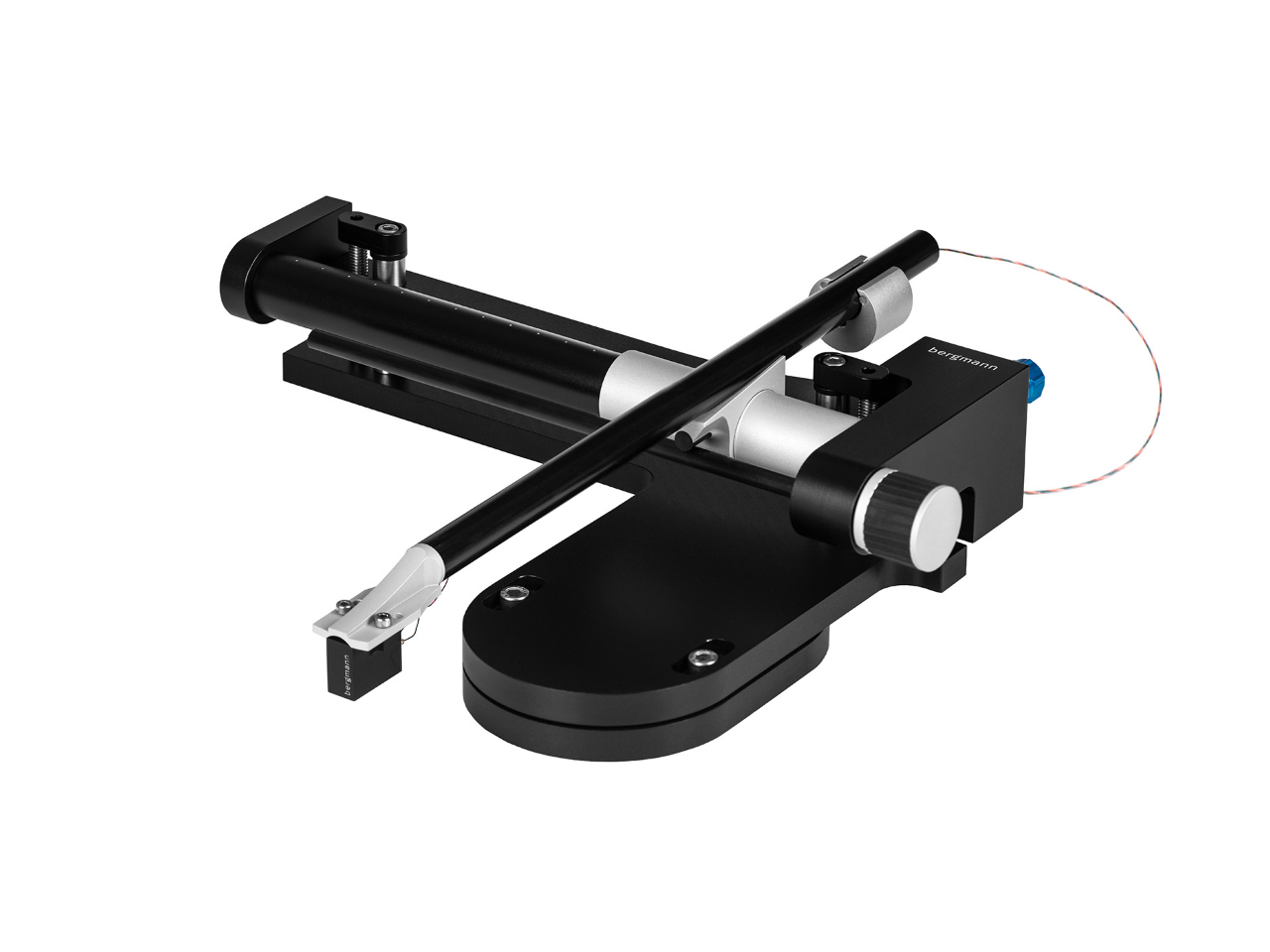

Design

In the design and construction of Odin, we stay to our idea of simplicity: As few parts and assemblings as possible, to avoid resonances.

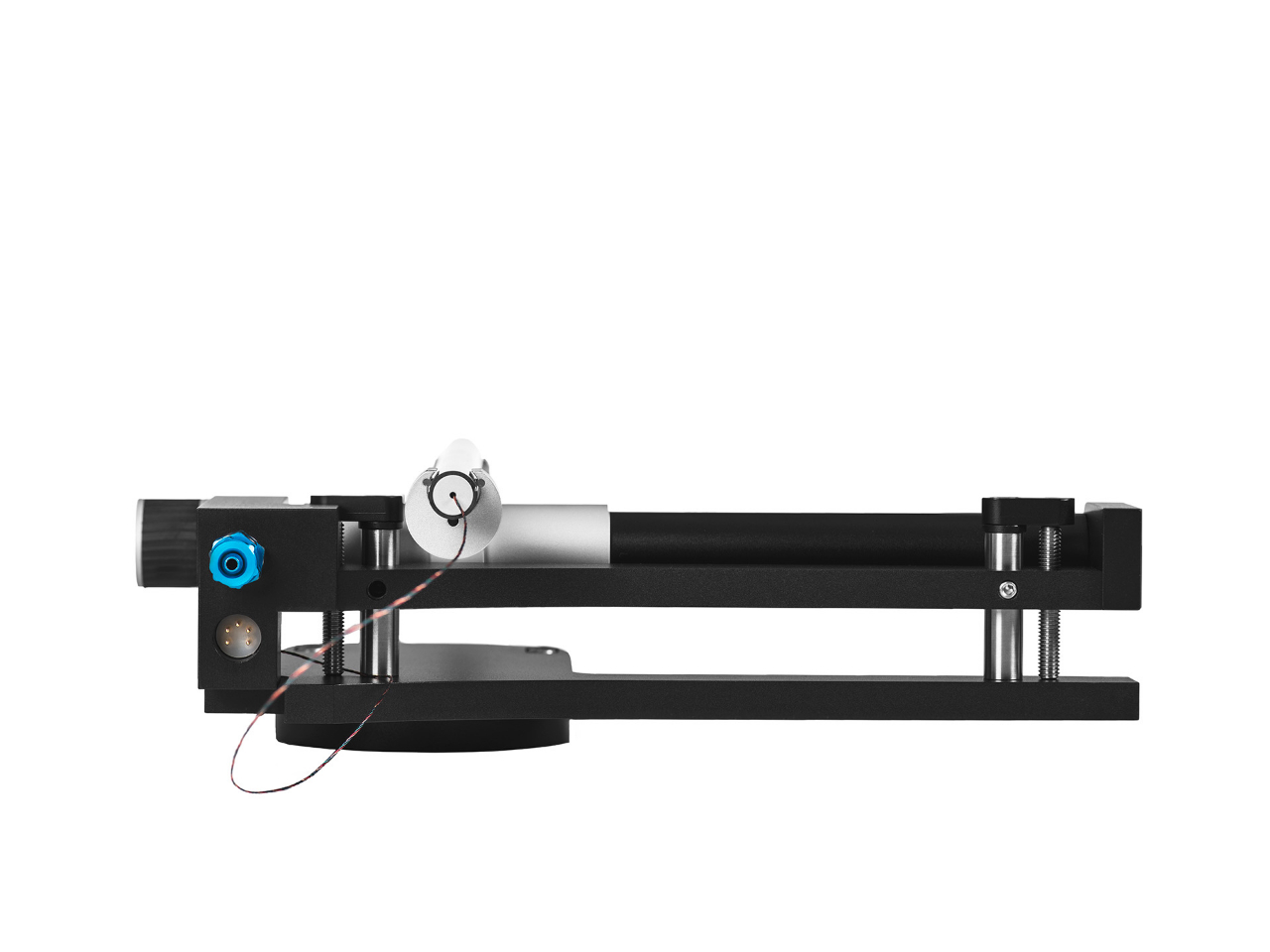

A parameter in the ultimate tonearm design is stiffness and stability in the construction. Both are carefully incorporated in the Odin arm. An example is the airpipe, which is fixed in both ends, to give the floating part the best possible base.

The armtube is traditional for Bergmann tonearms- well considered construction in few parts, made as a double tube construction, with damping in between the tubes. This means that the armtube control the vibrations from cartridge and record grooves when handling the musical crescendos. The tonearm wire is- as usual in Bergmann tonearms- in one piece from cartridge clips to the DIN connector. The DIN connector ensures user flexibility for connection of the prefered interconnect phono cable.

Counterweight is decoupled from the arm- again to avoid any resonances.

Floating part – perhaps the most important part, of an airbearing tonearm!

The first part of the tonearm to handle modulations from the record groove and cartridge, is the moving part of the tonearm. Head shell, armtube, sliding pipe and counter weight, has to be well considered and well assembled, to avoid any resonances to disturb the delicate signal.

The head shell is a very stiff construction, machined of one solid piece of aluminium, glued by 2-component epoxy onto the seamless carbon fiber armtube, which is a double carbon fiber tube construction with damping in between, to avoid coloration to the sound. The armtube is fixed in a groove, on top of the sliding pipe, which is machined of 2 pieces of solid aluminium and glued by 2-component epoxy. The space between the airpipe and the sliding pipe, is 50 micron, as we found this as the most userfriendly.

The azimuth adjustment is very well considered – a slot on the bottom side of the head shell, where an “azimuth-plate” perfectly fit = 100% contact, the azimuth is simply adjusted by tighten or untighten the 2 screws holding the cartridge, and then twist the cartridge to a perfect azimuth. At Bergmann Audio, we don’t believe in a twistable head shell in the armtube, as this solution never will be as strong and stiff, as the construction we have made on the Odin tonearm.

The tonearm wire is made in one piece from the cartridge clips to the DIN connector, to secure as pure signal transmission as possible.

Headshell machined in solid aluminium. The design ensure optimal stiffness.

Azimuth plate. 100% contact to the headshell and cartridge.

Armtube is a double seamless carbon design, with damping in between.

Sliding pipe floats completely frictionsless on the airpipe.

Tonearm wire in one piece from cartridge clips to the DIN connector.

Counter weight, decoupled from the armtube by 3 rubber strings.

Air supply

The air supply has been the object of our greatest attention. The goal is to design a silent air supply, which could be placed in the listening room, and deliver an even, clean and dry air flow.

The pump is an oil free, long life unit, which do not require much maintenance. The impulses from the pump are absorbed in an encapsulated reservoir. This results in an even airflow to the air bearing. The air supply is mounted with a filter, which prevents dust particles in entering the system. The filter is replaceable when necessary

Tekniset Tiedot:

Turntable

- Airbearing design.

- Vacuum hold down, or clamp.

- Accept up to 4 tonearms. All tonearm designs, radial – and linear tracking.

- Output for an airbearing tonearm.

Plinth

- Black coated die cast aluminium.

- Platter/Bearing

- Aluminium platter floats on air. 3mm acrillic mat

- Centred by hard anodized spindle/hardwearing low friction polymer bearing

- Platter weight: 11.8 kg

Feet

- Adjustable feet. Aluminium/ceraball construction

- Dimensions 365 x 480 x 190mm (D x W x H)

- Total weight: 38.0 kg

Motorbase

- Tacho motor with high precision feedback control system

- 33 & 45

- Belt driven

Airsupply

- Silent, clean, dry and smooth airflow. Replaceable filter.

- Easy accessible dust filter, for easy cleaning and replacement.

- Dimensions: 465 x 225 x 235mm. (D x W x H)

- Weight: 18,2 kg

Tonearm

- Linear tracking airbearing tonearm

- Aluminium/carbon

- Armtube damped inside

- Counter weight decoupled from armtube

- Adjustments: VTA, overhang, leveling. Tracking force

- Wire: Pure copper litz

- Clips: Gold plated copper

- Connectors: Gold plated DIN

- Effective mass: 14g

- Weight: Incl. armboard, 1.180g

Armboard

- Aluminium

- Dimension: 70 x 190 x 265mm (K x L x P)

Airsupply:

- Silent, clean, dry and smooth airflow. Replaceable dust filter.

- Dimensions: 135 x 155 x 330 (L x L x P)

- Weight: 5.7kg

Bonus

Tämän levysoittimen nettiostaja saa kaupan päälle vinyyliharrastajan selviytymispakkauksen. Pakkaukseen sisältyy levyharja, neulaharja ja mekaaninen neulavaaka. Edun arvo on n. 50 euroa.

| Väri | Musta, hopea |

|---|

Tutustu myös

-

-

-

Rega Planar 10

alk. 5499,00 €Regan paras levysoitin kautta aikojen – se on koettava! Demokoneemme uudella Apheta3-rasialla.

-

Naim Audio ND 555

alk. 20999,00 €Naimin uusi referenssiverkkosoitin, ND 555, on aito lisä valmistajan huippuluokan 555-sarjaan.

- Etusivu

- Tuotteet

- Tuotteet ryhmittäin

- Tuotteet merkeittäin

- Käytetyt tuotteet

- MR Hifin edut

- Halutaan ostaa

- Info

- Uutiset

- Yhteydenotto

- English